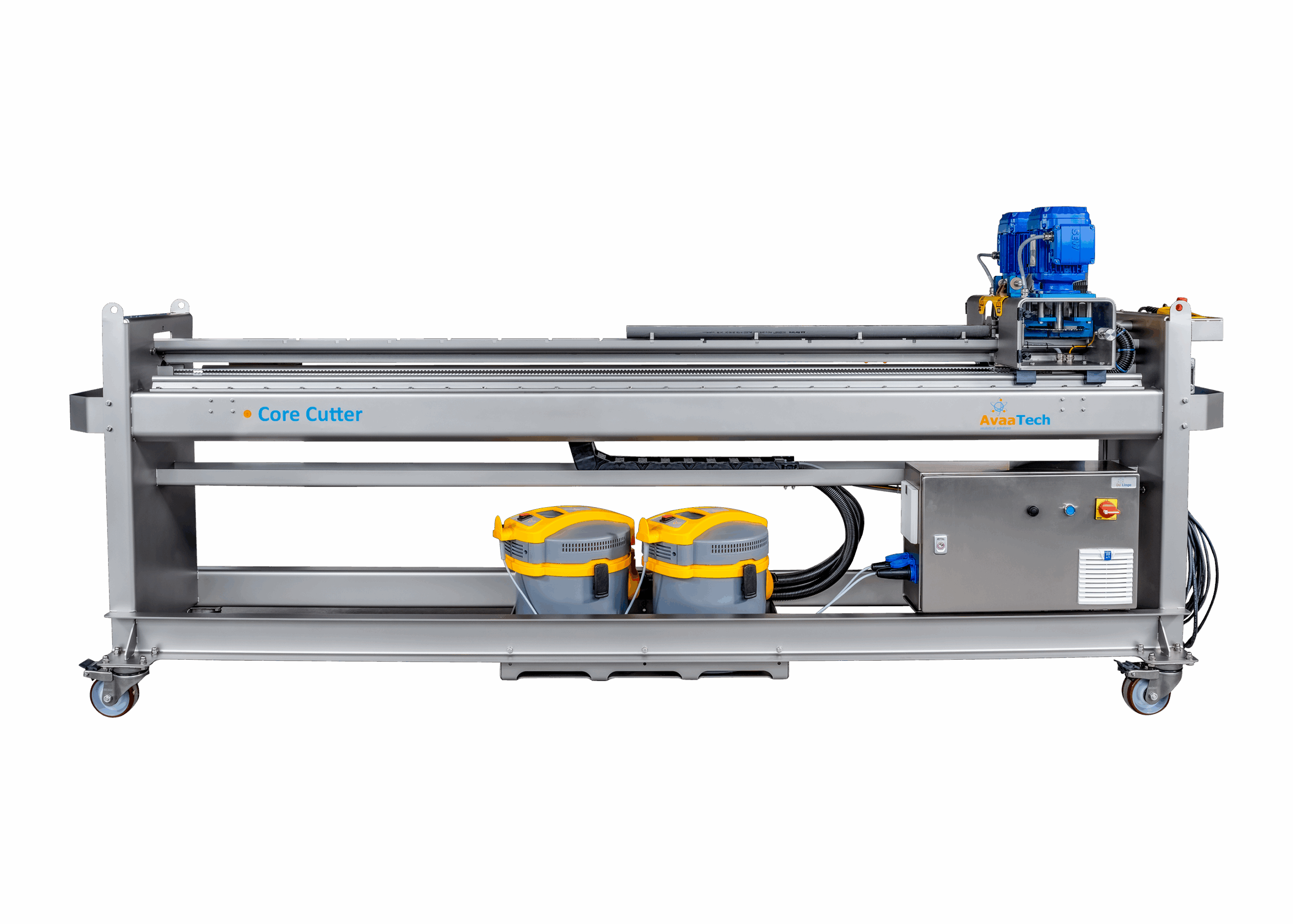

2m

max core length

<5min

cutting per core

7-13cm

core diameter range

1. Liner cutting

Using dual circular saws, the majority of the plastic core liner is cut and extracted by two high power industrial vacuum cleaners. By spinning the saws relatively slow compared to an angle grinder, the liner is not turned into dust but rather to shavings. Hindering unlimited spreading and allowing easier detection with the naked eye.

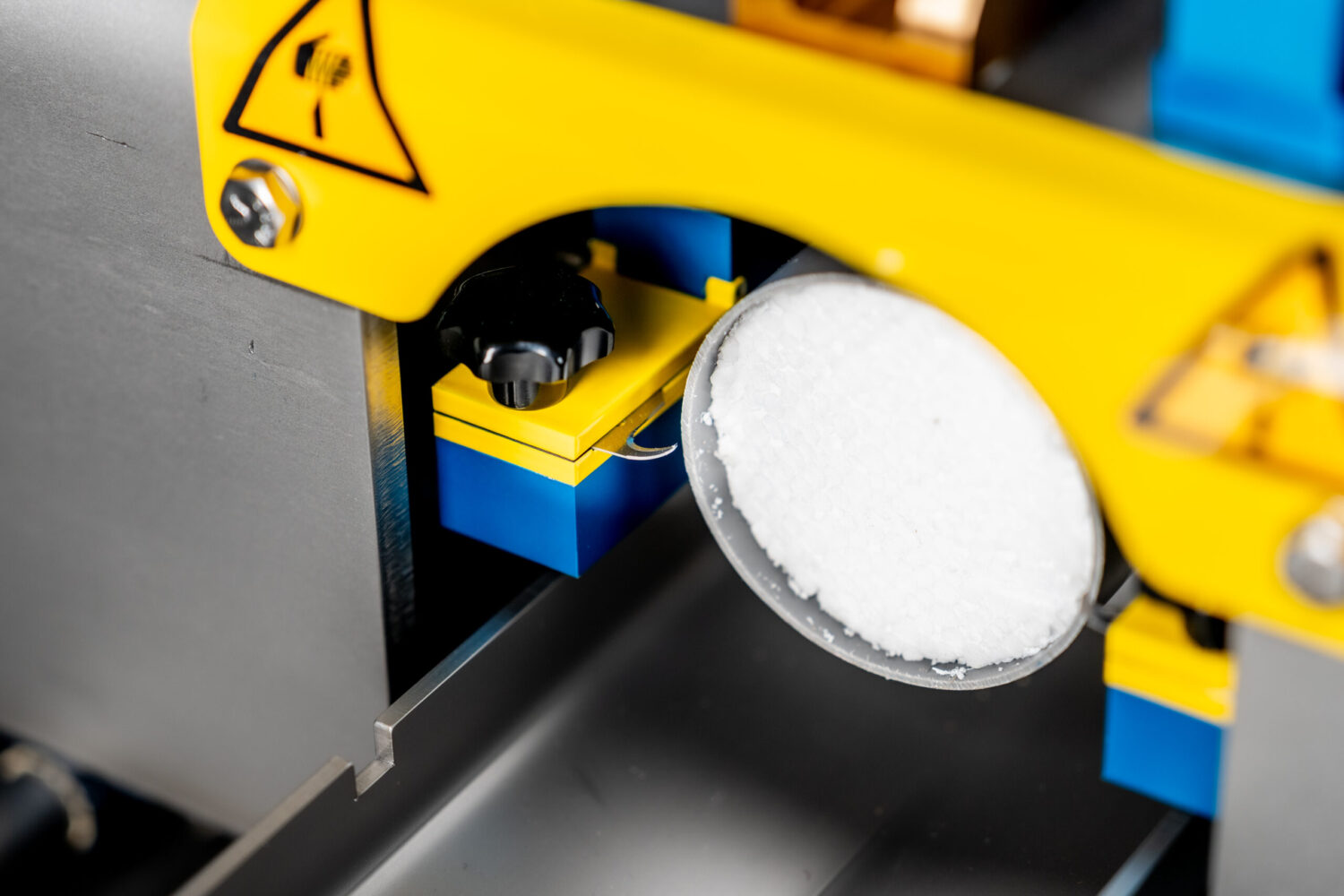

2. Liner Splitting

The last few millimetres liner is split by a hooked knife, positioned a few centimetres behind the saws. Splitting separately from cutting ensures no shavings can reach the sample before it is exposed.

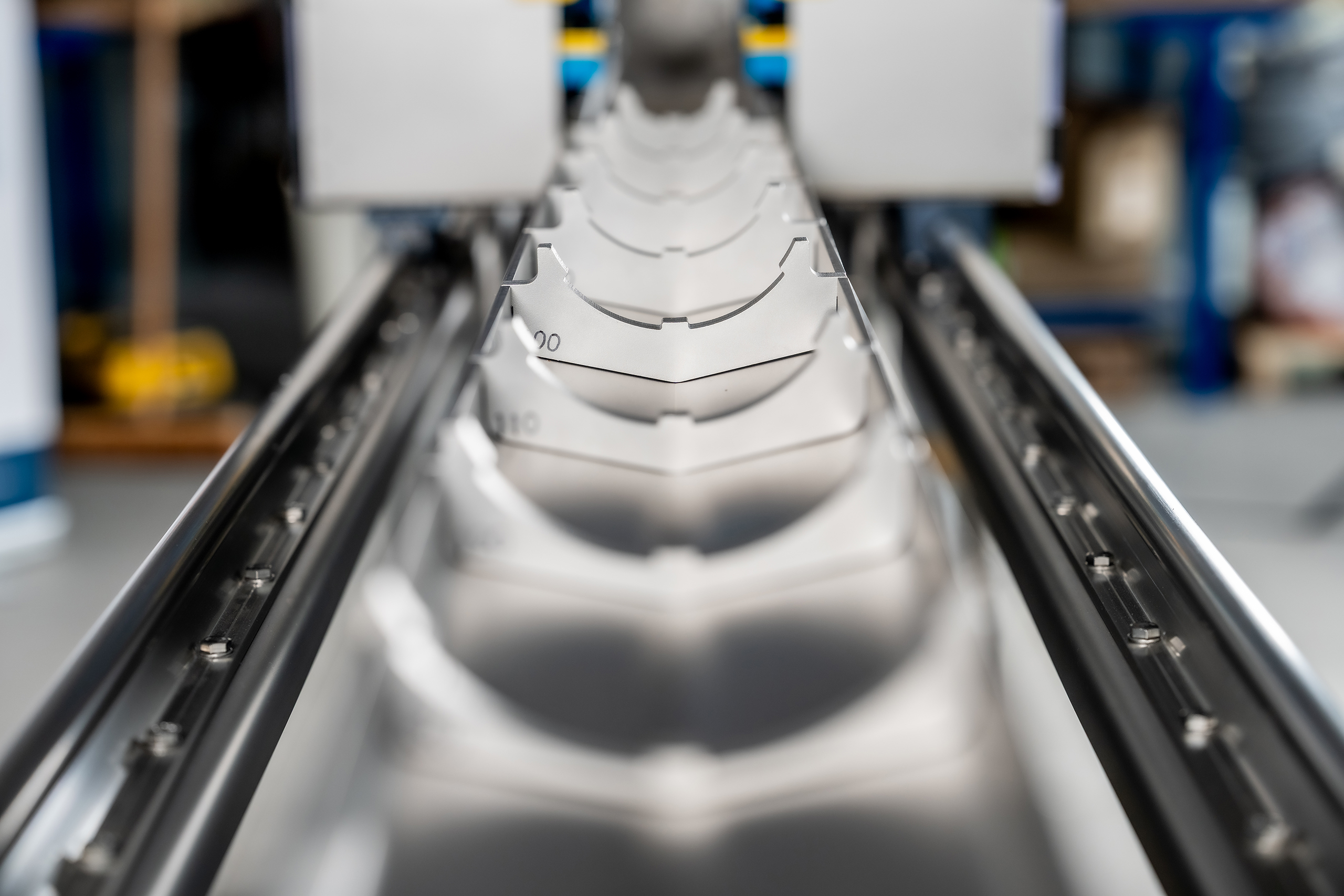

3. Sample Splitting

After the core liner is entirely cut and split, the operator splits the sample by hand with a 0.4mm diameter stainless steel wire. Tied at both ends at a metal pulling bar, the wire is pulled evenly by the operator through the sample without contaminating the sediment.